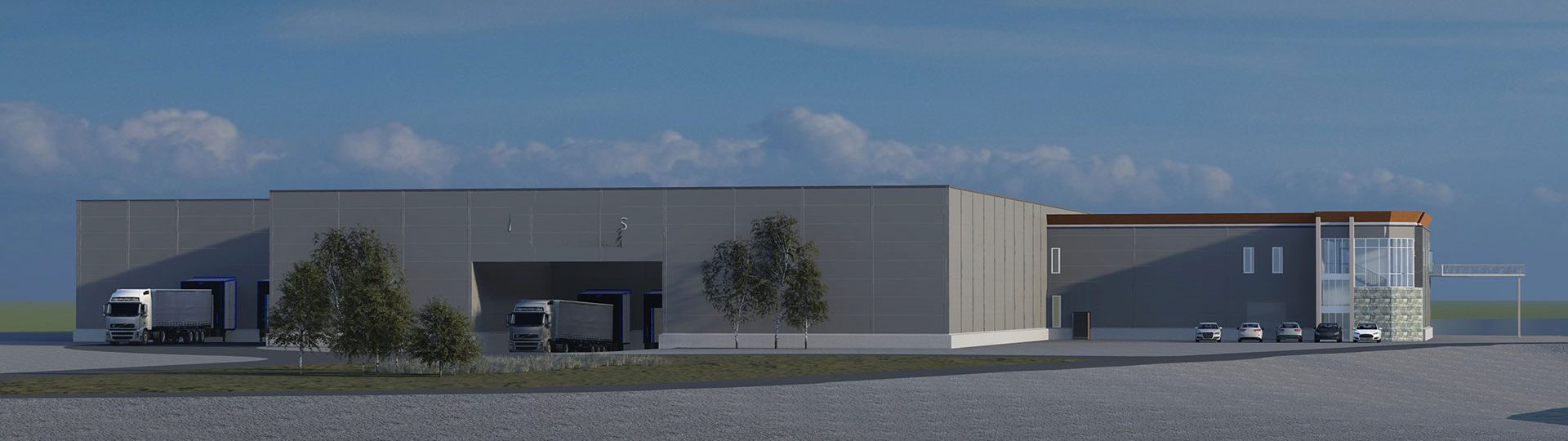

The new Bømlo facility is due to be completed in the fourth quarter of 2022. Hardanger Fiskeforedling harvests and packs salmon and trout for despatch to customers worldwide.

A forward-looking processing facility for salmon and trout is being built by Hardanger Fiskeforedling in a new fishing port at Langevåg on Bømlo. PTG will be providing it with an upgraded version of its well-tested plant for ice production, distribution and storage, as well as a refrigerated seawater (RSW) plant and other refrigeration systems. The whole delivery will be manufactured by PTG in Norway.

Sales manager Roy Arild Fjellstad at PTG Kuldeteknisk.

Sales manager Roy Arild Fjellstad at PTG Kuldeteknisk is pleased that the contract has now been signed and the company can start work seriously.

“This has been an important contract for us,” he explains. “The new plant will contain many of the products our group can provide. We’re able to supply everything the customer wants, and to deliver a complete system.”

New generation of well-tested ice system

The complete delivery of an ice system for production, distribution and storage involves a well-tested solution with a good reputation. Over the past year, PTG has devoted much time and resources to upgrading it further.

“Meeting new requirements and challenges introduced by the Norwegian Food Safety Authority has made a good system even better and given it even higher hygiene standards,” says Fjellstad. The contract with Hardanger Fiskeforedling is worth about NOK 15 million.

The biggest heat pump manufactured by PTG being driven out of the Malmefjorden factory on its way to what will become Salmon Evolution’s land-based fish farm.

Forward-looking facility

According to kyst.no, the fish processing facility is set to occupy a central and forward-looking position in a new fishing port under construction at Langevåg. This development covers 2 000 square metres of new buildings as well as the conversion of 2 000 square metres in existing structures and new process equipment for the factory.

The latter is being constructed to receive fish from waiting cages, harvest boats and wellboats, and includes refrigerated tank capacity for 250 tonnes of fish. It is being designed with an eye to flexibility for the customer, sustainability and cost-effective handling of residual raw materials.

Production in Norway

“We’ve assembled some of the companies which rank among the best in Norway for temperature control into a single group,” says Fjellstad. “By combining expertise built up in different teams, we can now deliver even better products.”

PTG has both expanded and modernised its factory at Malmefjorden in Romsdal, where the RSW plant and the refrigeration and ice systems for Hardanger

Fiskeforedling are to be manufactured.

“We’re proud not only of having a big team for developing new products but also of being able to produce them in Norway,” Fjellstad adds. “This means that we can fully guarantee the quality we deliver.”