The growing focus on battery production in Norway is no coincidence. The cold and dry climate provides ideal conditions for manufacturing high-quality battery cells, making temperature control and environmental stability essential in production facilities. This is where EPTEC’s delivery plays a key role in ensuring optimal temperatures.

Climate- and Energy-Smart System

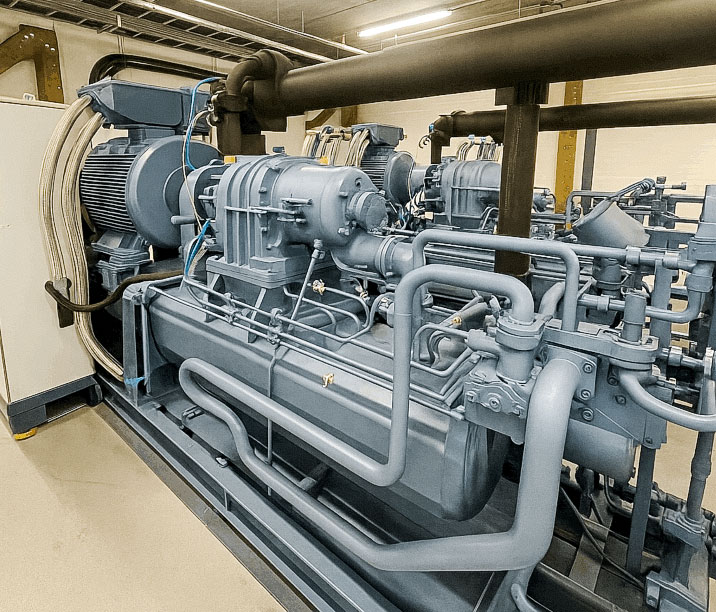

The cooling system consists of five ammonia-based GEA BluAstrum chillers with a combined cooling capacity of 8 MW, as well as five Kelvion dry coolers with a total capacity of approximately 10.5 MW. The system is modular and prefabricated, ensuring high quality, fast installation, and smooth commissioning.

The chosen refrigerant is ammonia. Ammonia (NH₃) is a natural refrigerant with zero global warming potential (GWP 0). It is not a greenhouse gas and therefore does not impact the climate. At the same time, ammonia has excellent thermodynamic properties that provide high energy efficiency and low power consumption. As battery production is energy-intensive, this is crucial for reducing overall energy use.

“We are proud to have contributed to an ambitious project with a strong focus on sustainability, quality, and innovation,” says Sveinsen.

Børge Sveinsen, sales and project manager at EPTEC Energi AS.

In addition to choosing the refrigerant, EPTEC has placed great emphasis on designing and delivering a flexible system that combines high performance with low energy consumption. The five dry coolers can be used for partial or 100 percent free cooling when outdoor temperatures are sufficiently low, allowing cooling to occur without the use of compressors.

“This delivers significant energy savings throughout the year and contributes to energy-efficient cooling,” Sveinsen concludes.

About the Delivery

- 5 GEA chillers (ammonia NH₃): 1.6 MW each = total 8 MW

- 5 Kelvion dry coolers: total capacity 10.5 MW / 6.58 MW free cooling

- Automation and electrical: Complete automatic control system including drawings, programming, and testing

Contact me if you want to know more about such cooling plants

Børge Sveinsen

Sales and Project Manager

Tel: +47 919 01 657

borge@eptec.no