The new delivery to Sævareid will ensure optimal temperature control, high energy efficiency, and better utilisation of energy from wastewater. Equipment delivery is scheduled for late 2026, with commissioning planned for spring 2027.

In-demand smolt

Sævareid Fiskeanlegg is a leading smolt producer, established in 1978. With its unique location at the innermost part of Sævareidfjorden, access to pristine freshwater from the Skogseid watercourse, and a combination of modern flow-through and RAS technology, the company delivers high-quality smolt with full traceability. Sævareid has strong local roots and is part of the Bolaks Group.

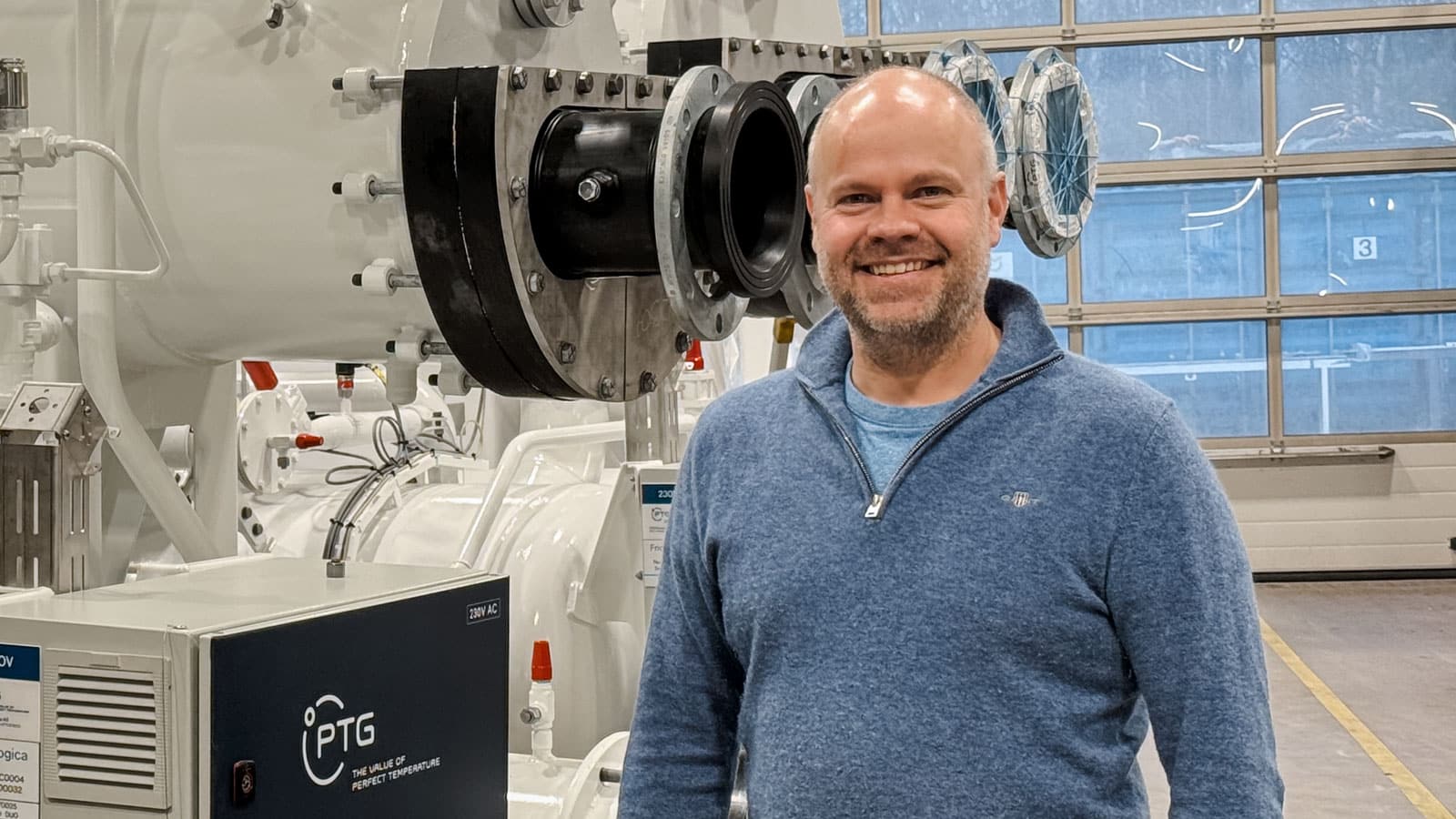

“For us, it is essential to have stable and energy-efficient solutions that support good fish welfare and sustainable operations. We have had excellent experiences with PTG Frionordica’s heat pumps since the first delivery back in the 1980s, and we look forward to integrating the new technology into our facility,” says Gudmund Midtrød, Technical Manager at Sævareid Fiskeanlegg.

Gudmund Midtrød, Technical Manager at Sævareid Fiskeanlegg.

Decades of cooperation

This agreement continues a long-standing collaboration that began in the 1980s, when PTG Frionordica supplied the very first heat pumps to Sævareid Fiskeanlegg. Since then, the company has delivered a total of 15 heat pumps to the facility, contributing to stable and energy-efficient production.

“We are proud of the trust Sævareid Fiskeanlegg places in us, and pleased to continue our strong partnership with Artec Aqua. Our solutions are designed with a focus on energy efficiency, operational reliability, and environmental responsibility, and we look forward to contributing to the further development of the facility,”

says Johnny Valle, Sales and Marketing Director at PTG Frionordica.

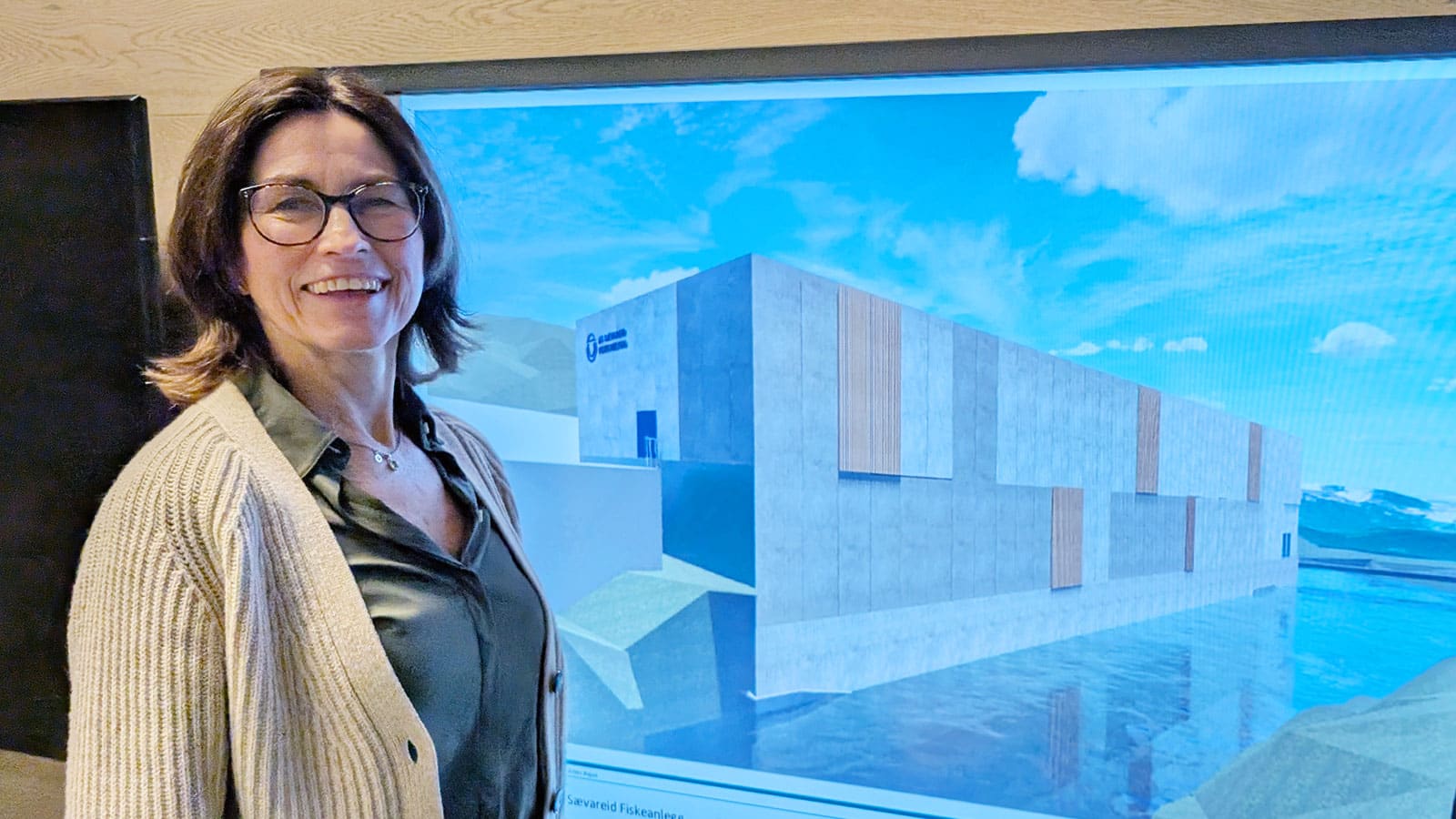

Sissel Walderhaug, Project Manager at Artec Aqua, also comments on the collaboration:

“This project is a good example of how we can combine new technology with proven solutions to deliver added value for the customer. Working with PTG Frionordica enables us to deliver a facility with high energy efficiency and low environmental impact,”

says Walderhaug.

Sissel Walderhaug, Project Manager at Artec Aqua.

New – reversible heat pump

Part of the delivery includes PTG Frionordica’s latest model – the FrioEco HPR DX ammonia reversible heat pump – combining environmental sustainability, energy efficiency, and compact design.

“This technology gives the aquaculture industry a new tool to reduce energy use and environmental impact, while enhancing operational reliability,”

says Johnny Valle at PTG Frionordica.

He summarises the delivery – and the benefits of the FrioEco HPR DX ammonia reversible heat pump:

- Reversal on the ammonia side – unique technology for efficient heating and cooling.

- Ultra-low ammonia charge: <100 g/kW, less than 25 kg for a 560 kW unit, reducing installation and machinery room requirements.

- Compact and easy to install: space-saving design that reduces installation costs.

- Environmentally friendly refrigerant: ammonia has zero climate impact, excellent technical properties, and 30–50% lower power consumption than alternative refrigerants.

Johnny Valle, Sales and Marketing Director at PTG Frionordica.

The delivery to Sævareid Fiskeanlegg will be fully manufactured at PTG Frionordica’s facility in Malmefjorden, Hustadvika municipality, on the Romsdal coast, and includes:

- 1 x HP 40000L

- 1 x HP 12000

- 2 x FrioEco HPR 1500 (new)

- A total of 10 plate heat exchangers for wastewater